ADTO News

Comparison Between PET Strapping & PP Strapping

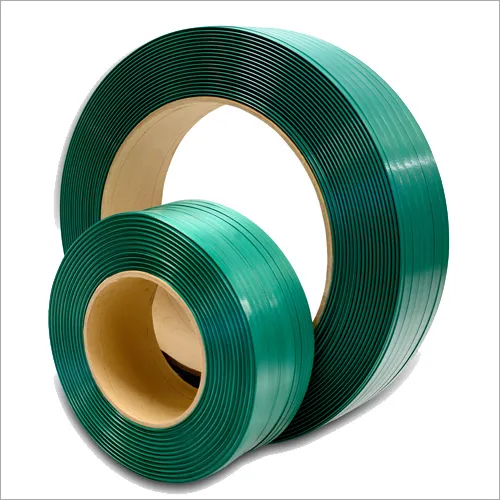

The most commonly used types of straps are Polypropylene (PP) straps, Polyester (PET) straps, and steel straps. Each type has its own unique properties, application areas, and advantages or disadvantages.

Steel strap was designed for extreme tasks for which a heavy or very firm strap is needed, whereby a high strength and minimum stretch is required, or when the product can be sharp or hot. Polypropylene or PP straps are the most commonly used straps and are used in a wide range of industries. PP strapping band has been specially designed for light to medium weight loads and is excellent under normal circumstances. Polyester or PET strapping band is the strongest plastic band. It is stronger than PP strapping band. It is often used for heavy loads that require a high tension. In many industries, PET is used as an alternative to steel.

Comparison Between PET Strapping & PP (Polypropylene) Strapping

PET Straps won't relax or elongate like polypropylene straps.

PET straps are more temperature resistant than polypropylene straps.

PET straps have a lower camber tendency compared to polypropylene (PP) straps.

PET straps will not break as polypropylene (PP) straps do when tightened too much.

PET straps have got greater strength than polypropylene (PP) straps of the same dimension.

PET straps can be tensioned up to 50% more than polypropylene (PP) straps of equivalent size.

Live Chat

Live Chat