Product Categories

- Scaffolding

-

- Ringlock Scaffolding

- Tube and Coupler System

- Frame Scaffolding

- Kwikstage Scaffolding

- Cuplock Scaffolding

- American Style Scaffolding

- American Scaffolding

- Cuplock System Frame System Scaffold Deck Tube & Clamp Multi-function Scaffold

- Scaffolding Planks

- Scaffolding Screw Jack

- Shoring Prop

- Ladders and Staircases

- Ladder Beam

- Scaffolding Accessories

- More Scaffolding

- Steel Prop Scaffold Clamps Kwikstage System Ringlock Scaffold System Base Jack Frame Scaffold System Screw Jack

- Steel Pipe

-

- Galvanized Steel Pipe

- Pre Galvanized Steel Pipe

- Square Steel Tubing

- Rectangular Steel Tubing

- Seamless Steel Pipe

- ERW Steel Pipe

- LSAW Steel Pipe

- SSAW Steel Pipe

- Pipe Fittings & Flanges

- Stainless Steel Pipe

- Stainless Steel Welded Pipe Stainless Steel Seamless Pipe

- More Steel Tube

- Pre Galvanized Steel Tube Square Steel Pipe Rectangular Steel Pipe ERW Steel Tube LSAW Steel Tube SSAW Steel Tube

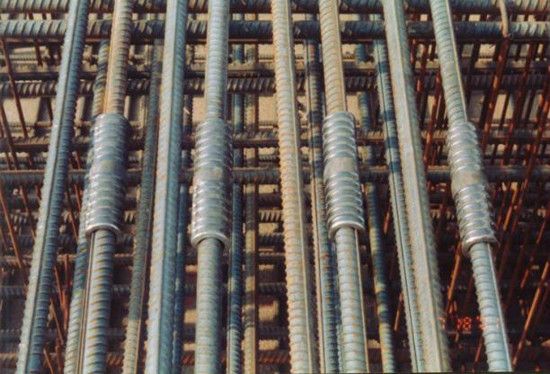

Cold Extrusion Rebar Coupler Product Characteristic

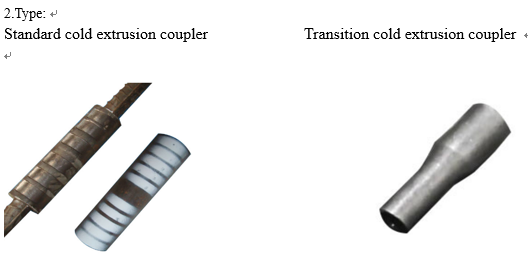

Material: Q345b / 20#seamless pipe

Introduction: Put rough metal in the cold extrusion die cavity, and then punch the metal on the press machine to create cold extrusion couplers through plastic deformation at room temperature.

Cold Extrusion rebar coupler is the outright solution for connection with ribbed rebar. Made of high-quality 20# carton structural steel. The cold extrusion rebar coupler enjoys high strength, and it is able to connect reinforcing bars with a diameter of 16 to 40mm. With no limitation on the type, composition, or weldability of steel bars, this rebar connector is widely used in bridge construction. It can meet with China standard of JGJ107-2010, the UK Standard of BS8110, the USA standard of ACI318, the VN standard of TCVN8163, and other internal standards.

Product Advantage:

1. Cold Extrusion Rebar Coupler is constructed of high-strength machinery steel grade 20 Carbo steel.

2. No special bar ends preparation needed

3. Most commonly used for connection in columns, beams, piles, etc, where rebar length is insufficient.

4. Do not inquire about the bars to be prepared, which can be operated with light tools and require a minimal bar length

5. Quick and convenient operation to shorten the construction period and lower the cost.

6.100% ultimate tensile and yield strength of rebar. There is no open frame during the operation, which ensures high safety. The operation process is also eco-friendly, as there is no pollution caused.

8. No threading at ends and no reduction of the cross-sectional area of the bar.

9. According to the inspection of the National Construction Quality Supervision and Testing Center, the rebar coupler joint performance has reached the Grade I splicing rebar joint of JGJ107-2016 Industry Standard.

How to operate?

1. Put the standard cold extrusion coupler onto the rebar end, ensuring the length of this part is half of the coupler length;

2. Press the coupler laterally with the cold extrusion machine;

3. Put the other side rebar end into the coupler;

4. Press the coupler laterally with the cold extrusion machine.

Live Chat

Live Chat