Product Categories

- Scaffolding

-

- Ringlock Scaffolding

- Tube and Coupler System

- Frame Scaffolding

- Kwikstage Scaffolding

- Cuplock Scaffolding

- American Style Scaffolding

- American Scaffolding

- Cuplock System Frame System Scaffold Deck Tube & Clamp Multi-function Scaffold

- Scaffolding Planks

- Scaffolding Screw Jack

- Shoring Prop

- Ladders and Staircases

- Ladder Beam

- Scaffolding Accessories

- More Scaffolding

- Steel Prop Scaffold Clamps Kwikstage System Ringlock Scaffold System Base Jack Frame Scaffold System Screw Jack

- Steel Pipe

-

- Galvanized Steel Pipe

- Pre Galvanized Steel Pipe

- Square Steel Tubing

- Rectangular Steel Tubing

- Seamless Steel Pipe

- ERW Steel Pipe

- LSAW Steel Pipe

- SSAW Steel Pipe

- Pipe Fittings & Flanges

- Stainless Steel Pipe

- Stainless Steel Welded Pipe Stainless Steel Seamless Pipe

- More Steel Tube

- Pre Galvanized Steel Tube Square Steel Pipe Rectangular Steel Pipe ERW Steel Tube LSAW Steel Tube SSAW Steel Tube

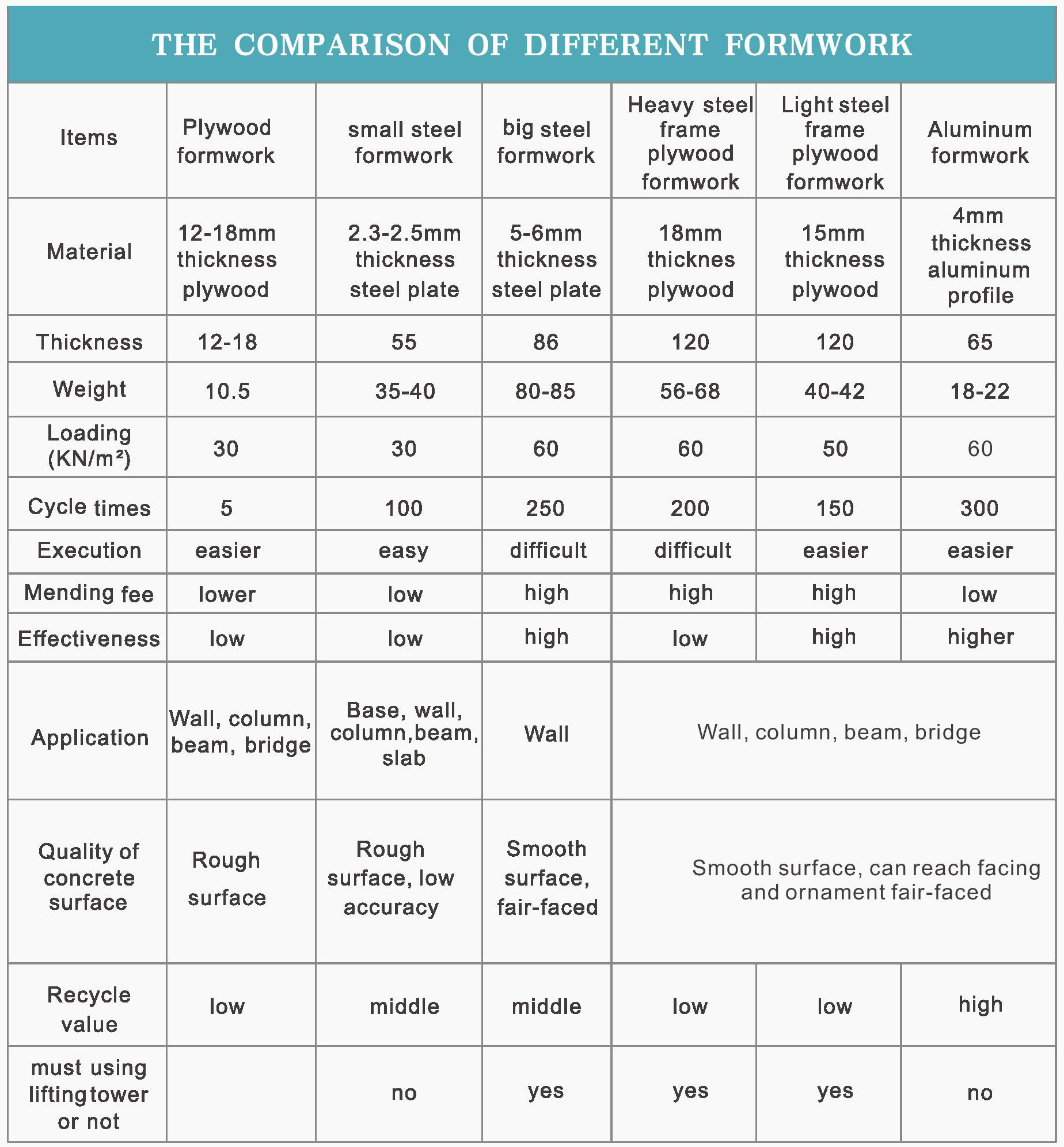

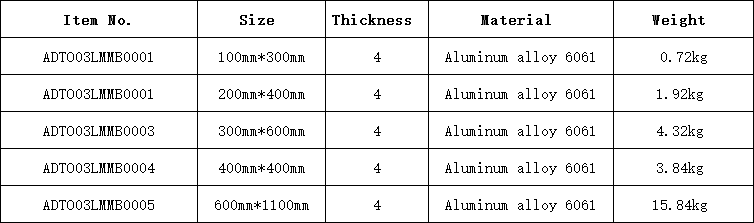

| Place of Origin | Hubei, China (Mainland) | Brand Name | ADTO | Model Number | ADTO-F11 |

| Aluminum Series Model | 6061-T6(GB5237-2008 stand) | Surface Treatment | Hot light body | Application | Tall building/sairport/towers |

| Weight per square aluminized | 20-28kg(Standards formwork) | Features | One-time Pouring, Over 200 times to resuses | Certificate | ISO9001:2008;CE;SGS |

| Standard Formwork Length | 2.7m,2.34m,1.2m | Aluminum thickness | 4mm | Components | Beam/Pillar/Wall/Prop/Floor/Reinforcement system |

Aluminum Formwork System Video

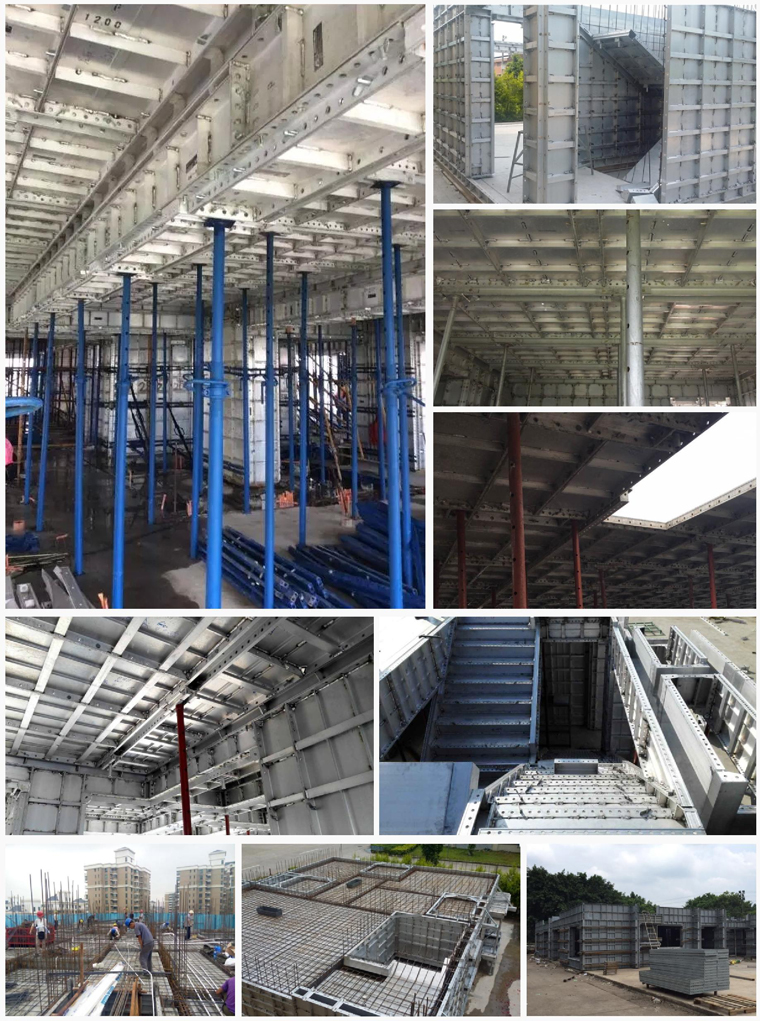

Aluminium Formwork System is a construction system for forming cast in place concrete structure of a building. It is also a system for

scheduling and controlling the work of other construction trades such as steel reinforcement, concrete placement and mechanical and

electrical conduits.

The System is fast, simple, adaptable and very cost effective. It is unique because it forms all of the concrete in a building including walls,

floor slabs, columns, beams, stairs, window hoods, balconies and various decorative features in exact accordance with the architects'

design. The dimensional accuracy of the concreted work also results in consistent fittings of doors and windows. The smooth-off form

finish of the concrete eliminates the need for costly plastering.

Advantages of Aluminium Formwork System:

1. Latest International Technique: Aluminum Formwork System is the latest international technique used world-wide.

2. High End Infra-Structure: The box type construction provides more seismic resistance to the structure as roofs & wall are tied with

reinforced bars provide cage like strength.

3.High Durability: The durability of complete concrete structure is far more than conventional brick masonry.

4.High Efficiency: Lesser number of joints thereby reducing the leakages, cracks and thus enhancing the durability.

5.High End Finishing: Integrated and smooth finishing of walls and slabs can be achieved on both sides of the walls.

6.Uniform Quality: Uniform grade of concrete is used and quality is maintained with the help of reinforced bars instead of local Bricks.

7.Less Maintenance: Strong built-up concrete structure needs no maintenance even for consumer.

8.Faster Completion: Fast Construction time bounds projects are achieved with the help of this system.

9.Saving Human Labour: More cost savings is achieved as no labour is required for plaster work, for Out Side Shuttering and Brick work. Lesser the human force more is the efficiency in quality.

10.Earth Quake Resistance: The natural density of concrete wall result in better sound transmission coefficient.

11.Eco Friendly: Max Aluminum Formwork System is more eco-friendly as compare to old technique.

ADTO Aluminium Formwork can be used widely in the construction of residential units and mass housing projects. It is fast, simple, adaptable and cost – effective. It produces total quality work which requires minimum maintenance and when durability is the prime consideration. This system is most suitable for Indian condition as a tailor–made aluminum formwork for cast–in–situ fully concrete structure.

ADTO Industrial Group, Co., Limited, founded in 1998, ADTO is a leading building material supplier and manufacture in China, centering on R&D, producing and selling of building material of scaffolding, aluminum formwork, fastener and coupler, integrates business of steel, logistic and wire & cables service. The group has more than 10 subdivisions and four manufacturing bases, possessing the right to import and export with business coverages spanning over more than 50 places and areas. Over 5000 international big buyers keep ADTO as their long term business partner.

1. Experience: Founded in 1998, more than 17 years in construction materials manufacturing

2. Product Idea: Quality decided to safety, safety is the hard truth.

3. Certifications: ISO, CE, SGS, BV

4. Production base: Four factories, more than 400,000 square meters

5. OEM or Customized Service is available.

Person: Ms Zheng

Email: Info@adtomall.com

Skype: ADTOMall

Address: HuNan,China

![]() More detail, welcome to send inquiry.

More detail, welcome to send inquiry.

Live Chat

Live Chat